(bp, 4.Jun.2024) — It takes extraordinary engineering and technology to keep the world supplied with energy. The latest example – one of bp’s biggest-ever projects – is coming together in the deep waters of the Atlantic Ocean, off the coast of West Africa.

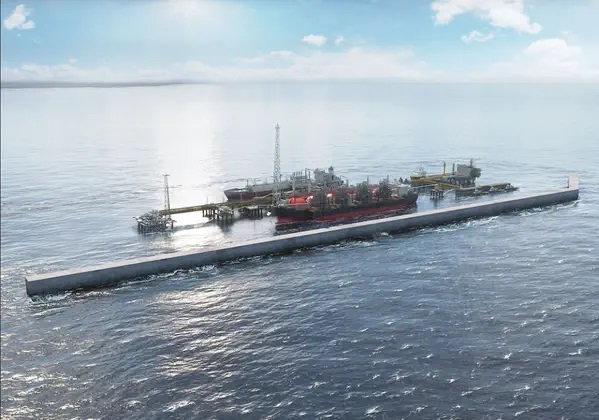

Seven years in the making, something remarkable is taking shape in the ocean where Mauritania and Senegal meet. A project, which includes a breakwater, subsea, a floating liquefied natural gas facility (FLNG), and floating production, storage and offloading vessel (FPSO) – each an engineering feat in its own right – is now in place as the finish line approaches for the development of the Greater Tortue Ahmeyim Phase 1 mega-project.

GTA Phase 1, as it’s known for short, is expected to produce up to 2.3 million tonnes of liquefied natural gas (LNG) per year, helping to meet global demand, and boosting the economies of these two developing economies.

“It’s a massive civil engineering project, two massive shipbuilding projects, and a massive pipelines project all in one – and they all need to be safely and flawlessly integrated,” says Alan Edwards, project general manager for GTA subsea.

Connecting the pieces

When complete, GTA will be operated by bp on behalf of its partners, including Kosmos Energy, PETROSEN and SMH. Here’s how the parts of this project work together to produce gas and LNG:

Subsea pipelines and infrastructure – the deepest in Africa – will feed into a floating production, storage and offloading vessel (FPSO) that will process gas delivered from wells 2,800 metres underwater, around three times the height of the world’s biggest skyscraper, the Burj Khalifa.

Constructed in China over the course of six years, the FPSO arrived at its GTA home in May 2024, 40 kilometres offshore. With this final major piece of the puzzle in place, the project can move ahead towards commissioning, start-up and first gas production.

“The scale of the technology and engineering required for this project was in a league of its own. The FPSO alone came with a set of unique challenges – from transporting it to the Atlantic from China, to battling damaging typhoons,” says Anil Senol, project general manager tasked with the transportation and installation of the FPSO.

Connected to the subsea network by flexible pipelines, the FPSO will remove water, other liquids and impurities before the gas is transferred by another pipeline to a floating liquefied natural gas vessel (FLNG), called Gimi, which is owned and operated by Golar LNG.

Located 10 kilometres offshore, Gimi is berthed at a specially-built hub terminal. This includes a 1.25-kilometre-long breakwater made up of 21 giant 16,000-tonne concrete structures, each nearly the size of the Arc de Triomphe. It was constructed to protect both Gimi and visiting LNG carriers from bad weather.

Once the gas arrives at the FLNG facility, it will be cooled to temperatures below minus 160ᵒC to transform it into liquefied natural gas. In total, Gimi is designed to produce around 2.3 million tonnes of LNG a year. Visiting LNG carriers will then take the LNG to its buyers.

____________________